The Ultimate DIY RV Roof Sealant Buyer’s Guide

If you are anything like me, and love spending time on your RV, then you probably don’t realize that the roof has a problem until it’s almost too late. The good news is that you can dispel such worries by inspecting it on a regular basis, and applying RV roof sealant.

Many issues on your RV or motorhome roof often arise as a result of water damage, which can reduce the value of your camper. This is what makes regular check-ups so important.

Investing in a good sealant helps fix the cracks or seams on the roof of your RV effectively. But how do you know what works for you?

Continue reading to learn more, or jump straight to the Best RV Roof Sealant Reviews

Factors to consider when in the market for RV roof sealant

Factors to consider when in the market for RV roof sealant

While the summer rain is one of the reasons for water damage on RV roofs, it is important to understand you may have to deal with the occasional freezing and thawing from the winter as well. This is particularly true if you spend a lot of time in your RV, and even more so if you RV full-time.

Exposure to such elements often causes expansion, creating larger cracks and seams on the roof which serve as gateways for water to enter the RV. With that in mind, it is important that you keep several things in mind when shopping for an RV roof sealant to ensure that you make the right choice.

Every RV, motorhome, and travel trailer roof is unique in its own way

The first thing that you need to think about is what kind of material your RV roof is made from? Lack of knowledge of your RV roof material is the main reason why many people run into a wall, figuratively, when getting ready for a do-it-yourself repair.

Different RV roofs come in various materials, with the most common ones being fiberglass, rubber and metal. Every material has different care and maintenance requirements.

Fiberglass RV Roofs:

Roofs made from fiberglass are becoming rarer each day and a common characteristic is that they are expensive. Despite this, they don’t require a lot of maintenance; thus explaining why they are a preferred choice for many. Defining characteristics include:

- RV roofs made from fiberglass are smooth and very slippery when wet. Exercise caution when cleaning or attempting to repair.

- Fiberglass roofs are also very solid and hard. Unlike metals that flex when heated, this material is hard to the touch and has a very different feel compared to rubber.

- In some instances, you may need to purchase RV Fiberglass repair panels.

Metal RV Roofs:

While there are many metals used to make RV roofs, aluminum is the rarest of them. It is almost impossible to find an RV whose roof is made from aluminum. Like fiberglass, it adds weight to the RV but has fairly low maintenance.

Metal RV roofs look the same but the common characteristics are that they resemble metal and have support beams at 2-feet intervals. In addition, a metal RV roof can’t support a lot of weight. This explains why you should stay on the beams when you go up on it.

RV Rubber Roofing Material:

This is the most common roofing material when it comes to motorhomes and camper RVs. It comes in two types: Thermal Poly Olefin (TPO) RV roof and Ethylene Propylene Diene Monomer (EPDM) RV roof.

Some of the characteristics unique to rubber include:

- It is the only soft RV roofing material

- Most roofs made from rubber are white

- Roofs tend to get a chalky texture when they become old

Understanding what material the roof is made of is important when considering do it yourself RV roof repair. It makes it much easier during routine inspection to identify issues and know how to solve them.

The type of material also determines what kind of maintenance the roof requires, how often maintenance will be needed as well as the kind of products that should be used.

The difference between EPDM and TPO

Otherwise known as synthetic rubber, EPDM has been around longer than TPO. It is a popular building and RV roofing material due to its extreme durability. Many manufacturers also prefer it for its easy maintenance and lower cost.

Typical EPDM RV roofs don’t need any maintenance for the first ten years, which is more than can be said for other materials. One doesn’t have to apply UV protection and its installation is simple. As for sealing seams, all you need is something that provides good adhesion.

TPO is a relative newcomer when compared to EPDM and a popular option for RV roofing due to its puncture resistance.

Compared to taped or adhesive seams, TPO is heat welded making it up to 4x stronger than other roofing options. Many manufactures offer it in white to help with UV reflection. It also offers way better water resistance compared to EPDM.

Prepping your RV roof for repair

but first, check out this video by Dicor:

Cleaning up the roof to remove any dirt and debris is the first thing you should do before sealing any cracks. It’s also important that the roof is completely dry prior to repairs.

Exercise caution as the smallest mistake could elongate the seam or even crack a hole. Depending on how bad the damage is, the right RV roof sealant will vary.

RV Roof inspection

Keep in mind that while many membranes will last for up to 2-3 decades before any repairs are required, it is never a guarantee that the sealants or seams will. A crack or opening in the roof will explain any leaks.

These seams are often created by years of movement on the road and if combined with age, the damage becomes worse and the sealant detaches.

Regular inspections are vital, and failure to adhere to the correct inspection intervals can make a warranty void.

Proper repair materials are a must

Once you have identified any issues with your RV roof, the next step is to source the right materials. This may mean getting quality sealants used for RV roofs.

Whatever you do, try not to buy the wrong sealant. Many people make the mistake of using silicone products, and because they peel off right away, they end up being very disappointed.

Reviews of the Best RV Roof Sealants

When it comes to ensuring that your RV stays in tip top shape, using the right sealants is important to seal openings in the roof. That said, here are reviews of the best RV roof sealants that the market has to offer.

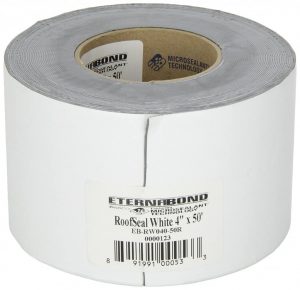

EternaBond RSW-4-50 RoofSeal Sealant Tape

This is perfect for sunny environments and the best part about its installation is that all you need is enough surface area. The factor needed for elongation is quite high to allow room for contraction or expansion with changing conditions. The adhesive side is lined with silicone, thus preventing attachment to other surfaces before use.

Pros

- One of the stickiest products you will find

- Almost fit for anyone

- Available in various widths

- The tight water cover on the white side can go over the gray semi-squishy adhesive that bonds to the surface.

Cons

- A warranty for atmospheric entry is not provided

- Pricey

Despite its shortcomings, this sealant tape is a real lifesaver when it comes to sealing cracks on the roof of your RV. It is especially for hot summers and will get you out of tight spots time and time again.

Dicor 501LSW-1 Lap Sealant

Offered in 10.3 ounce tubes, this RV roof sealant is compatible with EPDM sheeting. Additionally, Dicor 501LSW-1 Lap Sealant provides excellent adhesion to a variety of roofing materials including concrete, mortar, galvanized metal, wood, aluminum and more. When cured, it creates a waterproof seal on screw heads, along the edge of RV roofing, vent pipes, air conditioners and vents.

Dicor Lap Sealant Pros

- Works great for a variety of materials and applications

- UV stabilized and thus helps prevent discoloration and deterioration.

- Has the ability to remain continuously sealed and flexible.

- Particularly suited for Rubber, EPDM, & Metal RV roofs

- The sealant creates a waterproof membrane, thus preventing leaks into your R

- Flattens a little after application

- Works for various applications such as sealing screw heads, vents and pipes in vents

- Incredibly cheap!

Cons

- The sealant doesn’t come out of the tube as easily as other products, making application a difficult and slow process

- Though white, it turns pinkish orange when applied. This doesn’t sit well with many customers.

While it does have its fair share of shortcomings, the Dicor 501LSW-1 Lap Sealant offers more than one would expect at its price range. When it comes to applications where the surfaces need to stretch, this sealant is real contender. And while it is mainly recommended for rubber roofs, it works just as great for several other materials.

Liquid Roof RV Roof Coating & Repair

Available in six colors, this is one of the few RV Roof Repair sealants that are a Liquid EPDM coating designed to repair your RV roof quickly and permanently. If you want to enjoy the benefits of a weather-tight rubber RV roof, this is the product to purchase. Additionally, this multipurpose liquid coating cures into a waterproof membrane. It doesn’t contain any VOC’s or solvents as it is water-based.

Liquid Roof Pros

- Available in six colors

- Does not contain any VOC’s or solvents

- The perfect solution for someone who needs something resistant to freeze and thaw cycles

- Provides superb adhesion to various roofing materials

- Cures into a membrane that is waterproof

- Has a large coverage area

Cons

- Expensive

There are a few tricks you can implement for optimum effect. Rather than using it in direct sunlight, consider applying it in the mornings or evenings. Removing the painters as soon as possible is also important. Make sure that you apply a minimum of 2-3 coats.

Dicor RPCRC1 White EPDM Rubber Roof Coating

Designed especially for EPDM rubber RV roofs, Dicor RPCRC1 comes in a conveniently packaged coating ready for use. It forms one part of a two-part, commercial-grade system by Dicor that combines the acrylic coating with a cleaner. This white rubber coating has coverage of up to 1 gallon per 125 square feet.

Dicor White EPDM Rubber Roof Coating Pros

- Specially designed for EPDM roofs

- Has a large coverage area of 1 gallon/125 square feet

- Application is incredibly easy as only two coats are required for excellent results

- Doesn’t require much time to dry

- Doesn’t contain harsh abrasives, petroleum distillates or any citric ingredients that can damage your RV

Cons

- Applying it in the evening as the sun goes down isn’t the best strategy as it collects dew in the night and takes a few days to cure properly. It works best if used in the summer and in the morning. Using it when it’s sunny with no rain will also prove effective.

- Expensive

Despite the high price tag, Dicor RPCR1 is a great sealant for getting rid of ugly seams in the roof of your RV.

Conclusion

You will not be disappointed if you invest in any of the above products. The only trick lies in knowing how extensive the problem is and what you need to do to solve it.

Be sure to consider the material from which the RV roof is made, and pick up one or more of the recommended RV roof sealants listed above.

If you aren’t sure that these products are right for you, consider reading verified customer reviews on high authority sites like Amazon.

– RV Must Haves